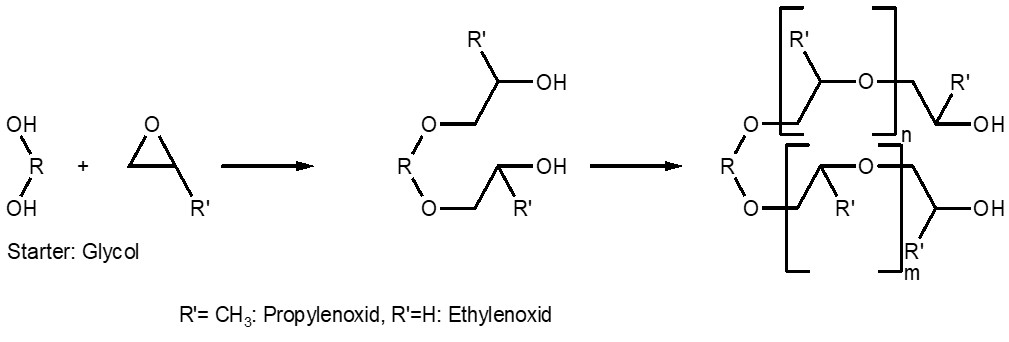

Polyether polyols

Polyether polyols are, without exception, synthetic polyols and are usually formed by chain extension of polyhydric alcohols in the broader sense as starters with ethylene oxide (EO), propylene oxide (PO) or a mixture of both. They exist at room temperature as viscous liquids and are available in an extraordinarily large variety of types.

Typical starters for the remarkably large variability of polyurethane chemistry are ethylene glycol, 1,2-propanediol, glycerol, sorbitol, bisphenol A or trimethylolpropane.

The properties of polyether polyols depend on their chemical structure. This includes the ratio of propylene oxide (PO) to ethylene oxide (EO) and the arrangement of these structural elements in the polyol.

The hydrophobicity is influenced by the use of EO or PO. Pure polyether polyols or predominantly EO are very hydrophilic and mix well with water. PO based polyols are significantly more hydrophobic and are preferred for use in cast resins, as the cured casting compounds have lower water absorption.

Due to their primary OH group ethylene oxide-terminated polyols have a significantly higher reactivity than propylene oxide-terminated polyols (secondary OH group). This influences their processing properties and their ability to crosslink in polyurethane systems.

The chemical structure of the polyether polyols is essential for their specific properties and applications.

The chain lengths of the polyether polyols used can be used to specifically influence the hardness of hardened cured parts.

Short-chain, rigid polyols tend to produce hard cured parts while long-chain, flexible polyols tend to produce soft, elastic cured parts. These polyether polyols are also resistant to hydrolysis by acids and bases and have good low-temperature flexibility.

We offer you a comprehensive selection of polyether-based base polyols. Simply get in touch with us!