Liquid rubber resins

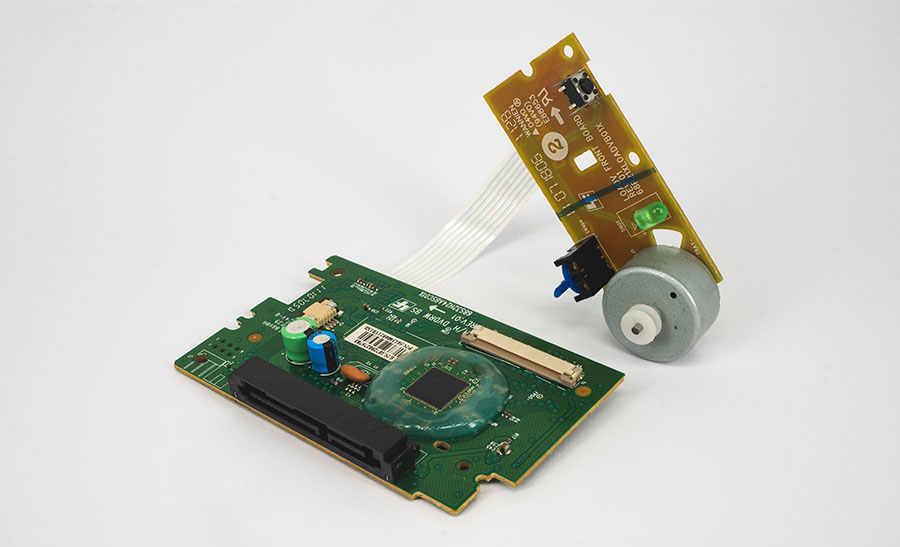

Liquid rubber resins are excellent for realizing soft to gel-like compounds despite their high hydrophobicity. Such systems are extremely advantageous for the encapsulation of sensitive electronic components. The mechanical load on such components is low when subjected to thermal shock.

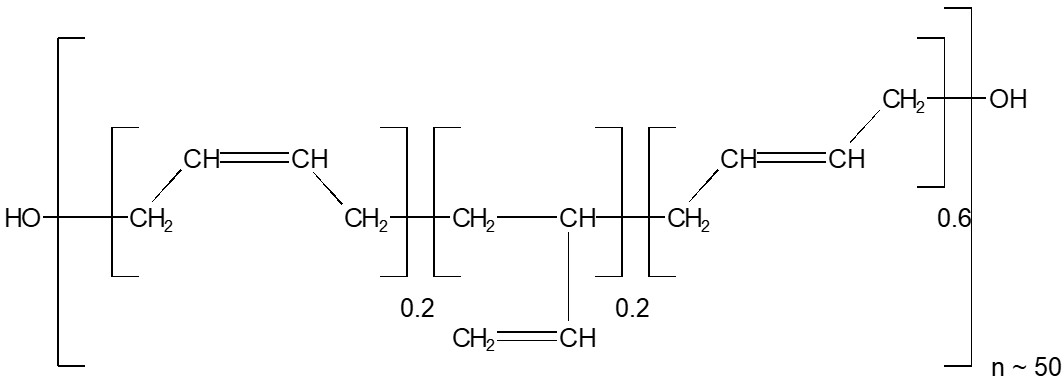

Potting compounds that are mainly based on so-called polybutadiene polyols (Fig. 1) are known as liquid rubber casting resins. Due to the very non-polar character of these casting resins, they have a pronounced hydrophobicity. This has an extremely positive effect on factors such as water absorption and diffusion permeability to water and moisture. Low gas permeability is another favorable property of the liquid rubber systems.

In addition, the non-polar character of this potting compound in many cases results in comparatively good adhesion to non-polar surfaces that are considered difficult in terms of adhesion. Another characteristic is excellent low-temperature flexibility, which is equivalent to that of silicones. Typical values for the glass transition point are in the range of - 50°C. Values as low as -80°C can be achieved through specific formulations and curing of the system.

By using suitable additives, the resistance to UV radiation and the limited temperature stability can be significantly increased. By adding thinners to the formulation, the comparatively high viscosities can be reduced to a very practicable level.

Product overview - liquid rubber resins

Below you will find a selection of our casting resins. Many other modifications are available on request.

For further information and data sheets, please click on the respective product.